Increased surface hardness,

strength and wear resistance

The increased hardness is due to martensitic transformation,

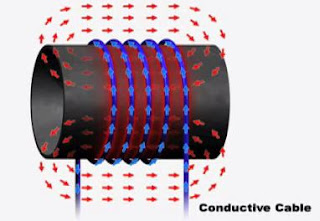

which is achieved in a selected area of the part by heating with an induction

coil followed by a rapid (water + polymer) quench Induction hardening.

Increased strength

and fatigue life due to the soft core and residual compressive stress at the

surface

This is a result of the hardened structure near the surface

occupying slightly more volume than the core.

Parts may be tempered

after induction hardening to adjust hardness level as desired

As with any process which produces a martensitic structure,

tempering will lower hardness while decreasing brittleness.

Deep case with tough

core

We can harden to case depths of up to .45” while maintaining

a soft core. Yes that’s .45”, nearly a half

inch! While case depths of .030” - .100”

are more typical, deeper case depths are achievable with the right

material. A deep case is appropriate for

larger parts under high stress, or parts which are still useful even after much

material has worn away.

Selective hardening

process with no masking required, areas with post-welding or post-machining

stay soft

Very few other heat treat processes are able to achieve

this.

Relatively minimal

distortion

Imagine a shaft 1” Ø x 40” long, which has two evenly spaced

journals; each 2” long requiring support of a load and wear resistance. Ultra Glow induction hardening is performed

on just these surfaces, a total of 4” length.

With a conventional method (or if we induction hardened the entire

length for that matter), there would be significantly more war page case hardening in Faridabad.

Allows use of low

cost steels such as 1045

The most popular steel utilized for parts to be induction

hardened is 1045. It is readily machine able,

low cost, and due to a carbon content of 0.45% nominal, it may be induction

hardened to 58 HRC +. It also has a

relatively low risk of cracking during treatment. Other popular materials for this process are

1141/1144, 4140, 4340, ETD150, and various cast irons. Lower carbon steels can be induction hardened

as well, although naturally the maximum hardness achieved will be lower. For example, 4130 will reach 50 HRC+ and is

much safer on parts prone to cracking during hardening.

On production runs of

medium to larger parts, induction hardening is frequently less expensive than

other heat treatments:

- It takes a less energy to heat just the area requiring hardening, rather than the entire part.

- Quenching is fast due to the water based quench and the reduction in heat removed oil coolers in Faridabad.

- Tempering is not required as frequently as it is with conventional heat treat.

- An atmosphere is not used, saving utility costs.

- There is no labor or material cost for masking.