Induction

Hardening is a type of heat treatment in which metal parts

are heated by electromagnetic induction and then quenched. It is also a type of

case hardening and can be used for many steel and steel alloys to improve

surface layer properties such as fatigue resistance and hardness.

Induction

Hardening Process

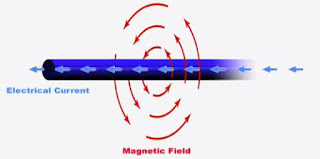

Induction Hardening can be split into two steps. The

first one is induction heating, in which electrically conducting metals are

heated with an electromagnet. The quenching phase follows directly after to

alter the surface structure of the material.

Induction

Heating

Materials such as steel are typically placed inside

a water cooled copper coil where they are subject to an alternating magnetic

field. They undergo electromagnetic induction by means of an electromagnet and

an electronic oscillator. This oscillator sends alternating currents through

the electromagnet, causing alternating magnetic fields that penetrate the

material. The results are eddy currents (loops of electrical current) which

heat the object within the coil. Induction hardening is a form of surface

hardening in which the depth can be up to 8mm. The deeper the currents

penetrate, the higher the frequency of the alternating magnetic fields have to

be Case

Hardening in Faridabad.

Steels that have a ferromagnetic structure (which is

inherited from the iron) can also be heated by magnetic hysteresis losses.

Magnetic hysteresis losses produce heat by re-aligning magnetic domains,

although it depends on the frequency of the currents, the penetration depth and

the properties of the material (size, density, alloys) how much heat can be

generated.

Quenching

Directly after the induction heating process, the

object has to be quenched, meaning that it has the be cooled down extremely

quickly. To do that, the workpiece is typically placed in a tank of oil or

water, although sometimes cold air is used. Quenching ensures that only the

surface is hardened and that heat doesn’t spread into the core of the material,

avoiding phase transformations from arising. Furthermore, the rapid cooling down

creates a martensitic or ferritic-martensitic structure on the surface layer.

These structure display higher tensile strength and low initial yielding stress

than a purely ferritic structure.

History

Induction heating was first developed and introduced

in its earliest form in 1831 by Michael Faraday. He could prove that an

electromotive force could be created by winding two copper coils around a

magnetic core while turning one of the windings on and off which affected the

other one. These currents were created by alternating magnetic fields around

the magnetic core. Because neither of the coils touch, the electromotive force

is induced into the second coil, the process was called induction heating.

Properties

that improve due to induction hardening

Deeper Case Depth: Induction hardening can penetrate

the surface of up to 0.31 inches (8 mm). This depends on the process of

induction hardening and the material’s properties.

Finer Grain Size: As mentioned above, induction

hardening changes the grain size on the surface of materials. A finer grain

size increases hardness because the surface is harder to penetrate.

Higher wear and fatigue resistance: Induction

hardening improves wear resistance because the structure of the surface layer

is altered. Ferritic steels obtain a martensitic structure which provides

improved wear resistance.

Induction

hardening in Faridabad is a good alternative to boronizing, which is a

type of surface hardening BorTec specializes in. Induction hardening is

recommended when only hardness should be improved. If you’re looking for a

treatment that can also improve adhesion, resistance against abrasive wear,

good stability at high temperatures and resistance against acids, the certified

BoroCoat treatment is the better choice. However, it depends on the area of

application and other factors which hardening technique is more suitable for

your needs.