Two

methods have become established for Induction

hardening work pieces in mass production: case hardening and

induction hardening. A comparison of these two methods shows their differences

and the advantages of each.

Case

Hardening vs. Induction Hardening – a Comparison

If

one compares the two methods for hardening steel work pieces (for a general

explanation of hardening see here: Hardening), then the first striking

difference is the parts handling. While case hardening processes a large number

of work pieces at the same time, induction hardening focuses on the individual

work piece. With induction hardening, components are hardened work piece by

work piece. For case hardening, “batch by batch” would be a better description.

Of

courses, this has an impact on the manufacturing. While case hardening relies

on parts logistics to carry parts between the production line and hardening,

induction hardening can be integrated directly in the production line with a

suitable hardening machine (e.g. MIND series) and be part of the cycle.

Case hardening in detail

As

mentioned above, case hardening is done in batches. As with induction

hardening, the goal is to harden the outer layer of work pieces.

In case hardening the work pieces are hardened by carburization. The steel is

heated to over 880 °C to become austenitic. Then coal is transferred into the

part from a CO-emitting medium through the part’s surface. The diffusion causes

the edge of the work piece to receive more carbon, while the carbon density

remains the same toward the center.

Hardening

occurs after the application of carbon. Penetration of carbon is critical for

the hardness and the depth hardness characteristic of the work piece. The

hardening, i.e. the hardness and the hardening depth, is defined by the

carbonization depth, the receptiveness and thus the harden ability of the

steel, and the quenching. The more carbon is inside an area of the work piece,

the more successful the hardening in that area.

After

hardening, the work pieces are annealed (for more information about annealing

please see here: Annealing) to restore some of their plasticity. The goal

of any hardening process is to make the edge resistant to mechanical loads

while giving the part enough elasticity to deflect external forces without

damage.

There

are two ways to influence the hardening depth in case hardening: One is to

manipulate the heating of the work piece, e.g. by application of special pastes

that prevent heating in certain places. The other is by influencing the

quenching process, e.g. by immersing only certain parts of the work piece.

With

both methods, results are not particularly accurate and reproducible only

within a relatively wide tolerance range. This is very different for Air Coolers and Oil Coolers in Faridabad.

With

both methods, results are not particularly accurate and reproducible only

within a relatively wide tolerance range. This is very different for Air Coolers and Oil Coolers in Faridabad.

Induction hardening in detail

As

mentioned above, each part is hardened separately with the induction hardening

technology. Each part is heat treated, quenched, and annealed (if necessary)

separately.

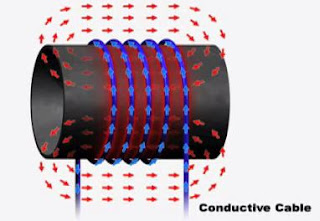

In

addition to integration in the production line, the great advantages of

induction hardening are precise control and reproducibility of hardening

results.

To

achieve this, the entire hardening process from the inductor and the applied

energy and frequency to quenching and annealing is specially adapted to the

relevant work piece. This yields excellent hardening results, even for work pieces

with complex geometriesen

ing

Which hardening method is the right one?

Which

Induction hardening in Faridabad

process is suitable for an application depends on several factors. Both

methods, case hardening and induction hardening, have advantages and downsides.

For

the mass production of components in medium or large quantities however,

induction hardening offers a range of benefits:

- With a suitable hardening machine, induction hardening can be fully integrated in the cycle of the production line and automated.

- Especially with induction hardening, results are reproducible, which contributes to a consistently high quality in production.

- This reduces unit costs considerably