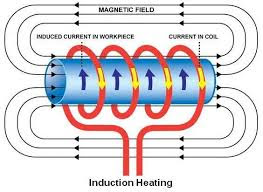

The Induction hardening faridabad works on the

electrical device principle. It’s additionally referred to as eddy current

heating. The currents square measure elicited by the principle of magnetic

attraction induction. The heating is also low frequency as within the case of

core sort induction chamber or high frequency because the case with coreless

induction furnaces. The example of indirect heating is that the indirect induction kitchen appliance that is most popular over resistance kitchen appliance attributable to its fine temperature management. It’s used for a similar purpose because the resistance kitchen appliance. Moreover, within the indirect heating methodology the eddy current square measure elicited within the heating parts by magnetic attraction induction that produces heat in heating parts. The warmth so made is transferred to the body to be heated by radiation.

Types of heating

- Direct heating

- Indirect heating

- Direct heating

In direct heating, the eddy

currents square measure made among the fabric itself that's to be heated. The

samples of direct heating square measure the high-frequency eddy current

heating used for case hardening or tempering of varied machine elements, tempering

of steel strip and fastening. Core less Induction hardening job work used for making ready

varied best steels additionally work on a similar principle.

There square measure primarily 2 forms of induction furnaces

- Core sort induction chamber

- Core less induction chamber

- Core sort Induction chamber

Core sort induction chamber is

basically a electrical device with the charge of metal to be heated as single

flip short circuited secondary and magnetically coupled to the first winding by

the iron core.

This flowing through the charge is incredibly

high is also of the order of many thousand amperes. From the figure, it's clear

that the coupling is loose and leak electrical phenomenon is high thus the

facility issue is low. To beat this issue, core sort induction chamber is

operated at a really low frequency say ten Hertz. The most disadvantages is

that magnetic attraction forces manufacture nice turbulence of the liquefied

metal that is beneficial to an exact purpose, however it becomes too severe

unless the frequency is unbroken low. Another disadvantage of this chamber is

that a melting pot is of inconvenient form from the scientific discipline

purpose of read. At the time of beginning, an entire ring of metal should be

gift the melting pot otherwise, the secondary circuit can stay open and warmth

won't be made. one more disadvantage is that it needs low frequency (10 Hz)

provide which needs frequency changer, that involves further value. On account

of the on top of drawbacks mentioned on top of core sort induction furnaces are

obsolete today.

Ajax Wyatt Vertical Core chamber

An improved type of core sort Induction hardening job work is mythical being Wyatt vertical core sort chamber. This

chamber is incredibly appropriate for continuous operation and it is operated

on traditional provide frequency i.e. 50 Hz. The core is formed of laminated steel

and also the secondary circuit is created by the only flip of liquefied metal.

The charge is given from on top of and also the liquefied metal is taken out

through the spout. The stirring action is made by the pinch result that is

proportional to the sq. of amp-turns. The secondary circuit is merely complete

once there's decent liquefied metal within the 'V' to finish the secondary

circuit. Just in case the mythical being Wyatt vertical core sort chamber is to

be unbroken long while not operation, a reduced voltage is applied that

provides only enough energy to stay the metal in ‘V’ within the liquefied

state.

Uses of mythical being Wyatt Vertical Core chamber

Therefore, mythical being Wyatt

vertical core chamber is incredibly appropriate for continuous operation. a

correct arrangement is formed for fitting the chamber to require out liquefied

metal. The facility issue of the circuit is regarding zero.8 and also the power

needed for the chamber so as to finish soften in an exceedingly affordable time

is regarding two hundred kW per ton. The soften is completed in regarding one

to a pair of hours for giant sizes and in lesser time for smaller sizes.

mythical being Wyatt Vertical Core chamber is

employed for melting and processing of non-ferrous metal like brass, copper and

Zn. Its potency is regarding seventy five %. Customary sizes of those furnaces

square measure sixty — three hundred kW, single section fifty Hertz acting at

600 volts.

Advantages of mythical being Wyatt Vertical Core chamber

- Control is straightforward.

- An ideal operating condition within the cool atmosphere with no dirt, noise or smoke.

- High power issue zero.8 to 0.85 relatively

- The absence of melting pot.

- Uniform stirring of charge provides the solid composition.

No comments:

Post a Comment